In the world of specialty chemicals, formulation stability does not end with their design in the laboratory. Transportation, often perceived as a standard logistical link, becomes a critical issue when products are heat-sensitive.

This is the case for a French manufacturer specializing in the distribution of varnishes, paints, and resins for finishing flexible materials. It supplies major players in the leather goods, footwear, and high-end upholstery industries.

For these customers, a product that has solidified, separated, or deteriorated, even slightly, can lead to rejection, loss of quality, or production non-compliance.

To ensure the thermal stability of its products during winter shipments, this distributor turned to COLD & CO to integrate passive and modular insulated solutions that are perfectly suited to its flows and field constraints.

Fragmented logistics, exposed to climatic variations

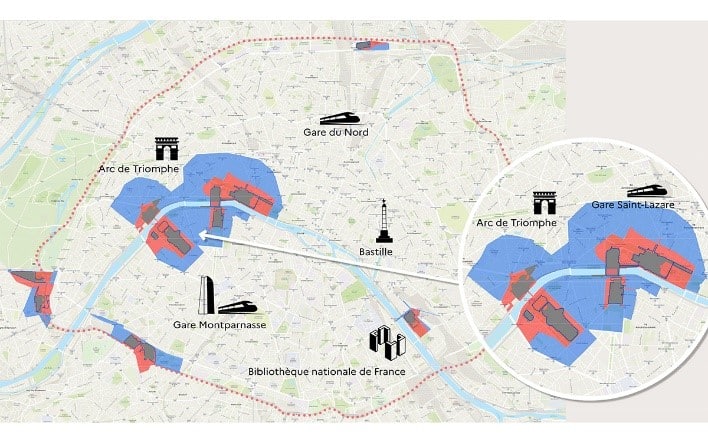

The company ships its products throughout France and to several European countries. While large volumes can be transported in refrigerated trucks, smaller shipments (jars, bottles, cans) are much more vulnerable.

In winter, there are many risks: unheated warehouses, load breaks on docks or tarmac, temporary storage in cold areas, etc. These hazards can be enough to crystallize a formula or alter its properties.

COLD & CO therefore proposed a differentiated response depending on the type of shipment, allowing products to be kept at a stable temperature without consuming energy.

Customized solutions for two logistics formats

For small individual packages, the company now uses 23L Freshbox+ containers with recycled cotton inserts. These containers maintain temperature for several dozen hours, simply thanks to the inertia of the products and the passive insulation of the box. A simple, effective, and environmentally friendly solution.

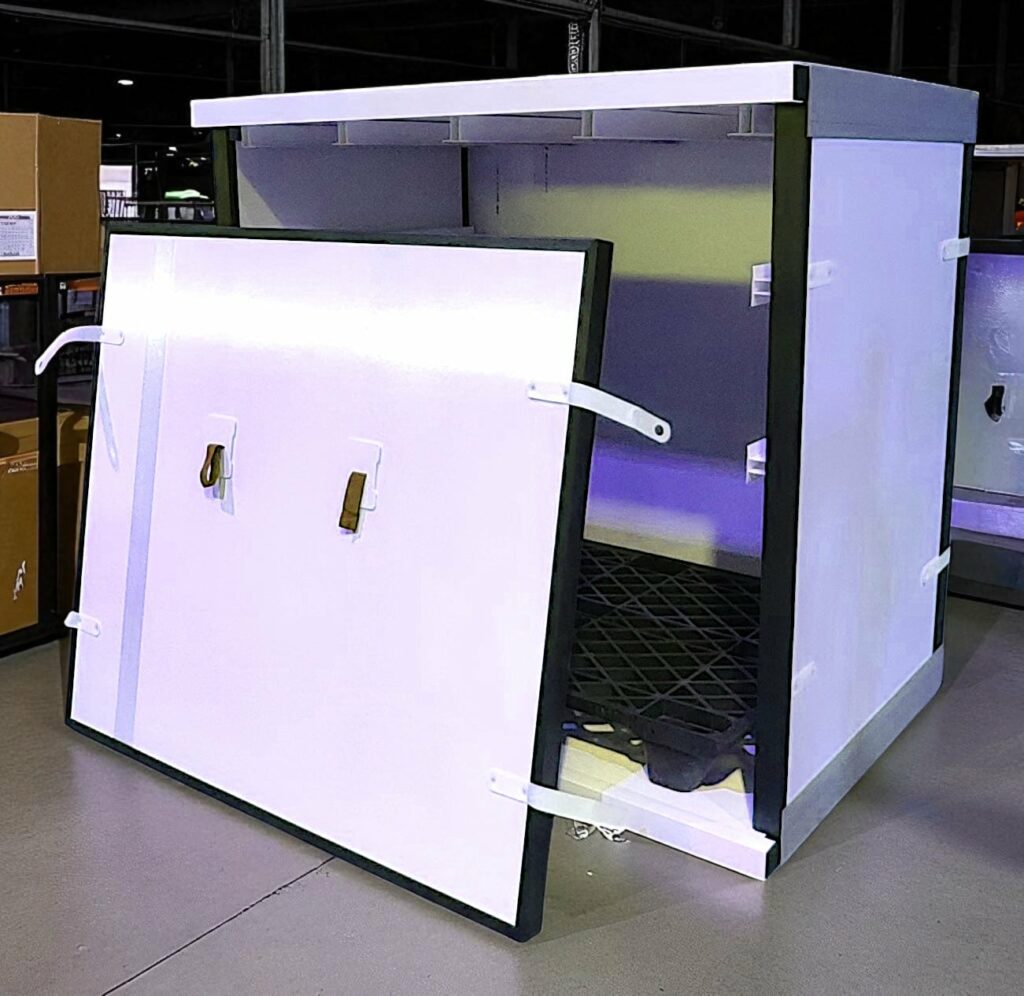

For bulk shipments, particularly to Eastern Europe, the CareExtreme Pallet has been deployed. This large-format insulated container can be assembled without tools, has a capacity of up to 900 liters, and guarantees a stable temperature for several days, even in difficult climatic conditions.

Another advantage is that it is reusable and folds flat to reduce return logistics costs.

Reliable logistics, aligned with regulatory requirements

These solutions have enabled the company to secure its shipments during the winter period, ensuring that products are kept in perfect condition until they reach customers.

They also comply fully with regulatory requirements for the transport of chemicals, particularly in terms of safety, traceability, and ADR compliance.

Responsible logistics, promoting more sustainable chemistry

This distributor is part of a responsible innovation strategy: formulations based on bio-based ingredients, reduction of VOCs, commitment to green chemistry programs.

The adoption of passive, energy-free, reusable, or recyclable insulated solutions extends this approach to logistics, limiting the carbon footprint of each delivery.

For specialty chemical manufacturers, transportation is becoming a decisive factor in quality and differentiation.

With COLD & CO’s support, this distributor has been able to combine thermal control, operational simplicity, and environmental consistency to deliver high value-added products.

Do you also have products that are sensitive to temperature variations?

Contact our COLD & CO experts for a tailor-made solution!