A refrigeration logistics revolution at the service of agility, economy and sustainability

A French leader in home food delivery recently redesigned its fleet and delivery practices. Exit the refrigerated trucks, place to a more agile and economical solution: passive refrigeration with the isothermal and refrigerated CarryTemp containers from COLD & CO.

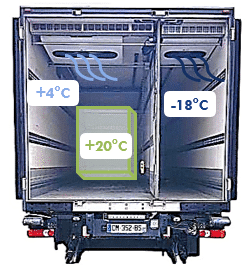

1. From a compartmentalized tri-temperature cold truck to a modular dry cold truck

1.1. The tri-temperature truck: a structured but not very flexible solution

The brand initially operated with tri-temperature trucks, with compartments dedicated to dry, cool and frozen. This model allowed for compliance with temperature constraints by type of merchandise, but remained inflexible and cumbersome. Fixed partitions limited modularity and reduced the available usable volume.

1.2. The combined mono-temperature truck : a step towards simplification

Five years ago, a first shift was initiated with the abandonment of tri-temperature in favor of mono-temperature trucks set for fresh, combined with the use of isothermal containerss CarryTemp fitted with -21°C plates for quick-frozen products. |

This new configuration, simpler, however, shows limits: in the absence of a specific compartment, dry products were stored at 4°C, an energy aberration that led to unjustified overconsumption.

Added to this were high economic costs :

- Rental of more expensive refrigerated vehicles,

- Heavy and frequent maintenance of the cold group,

- Overweight of the vehicle, reducing payload and increasing consumption,

- And a poorly optimized use of interior space.

This observation was a key trigger in the reflection on a more agile, more rational… and more sustainable model.

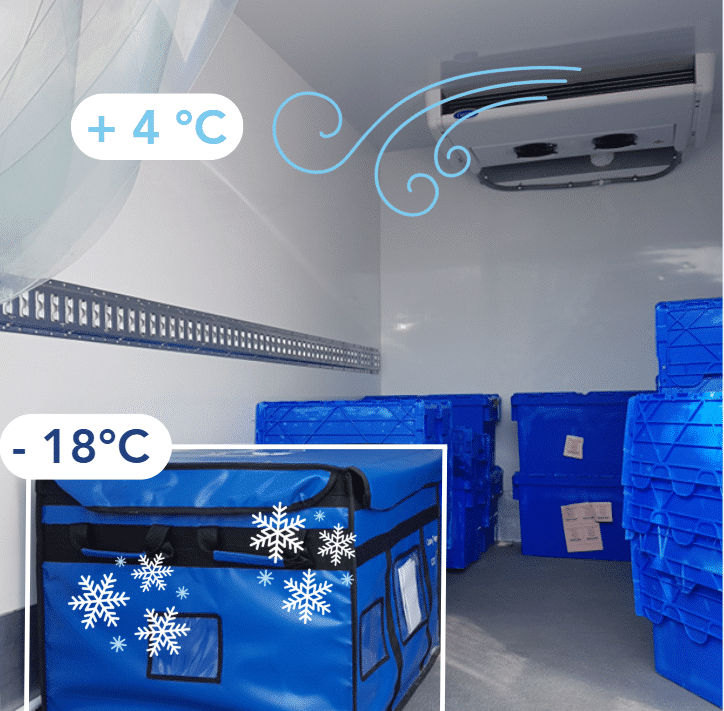

1.3. The dry truck in multi-temperature passive cold

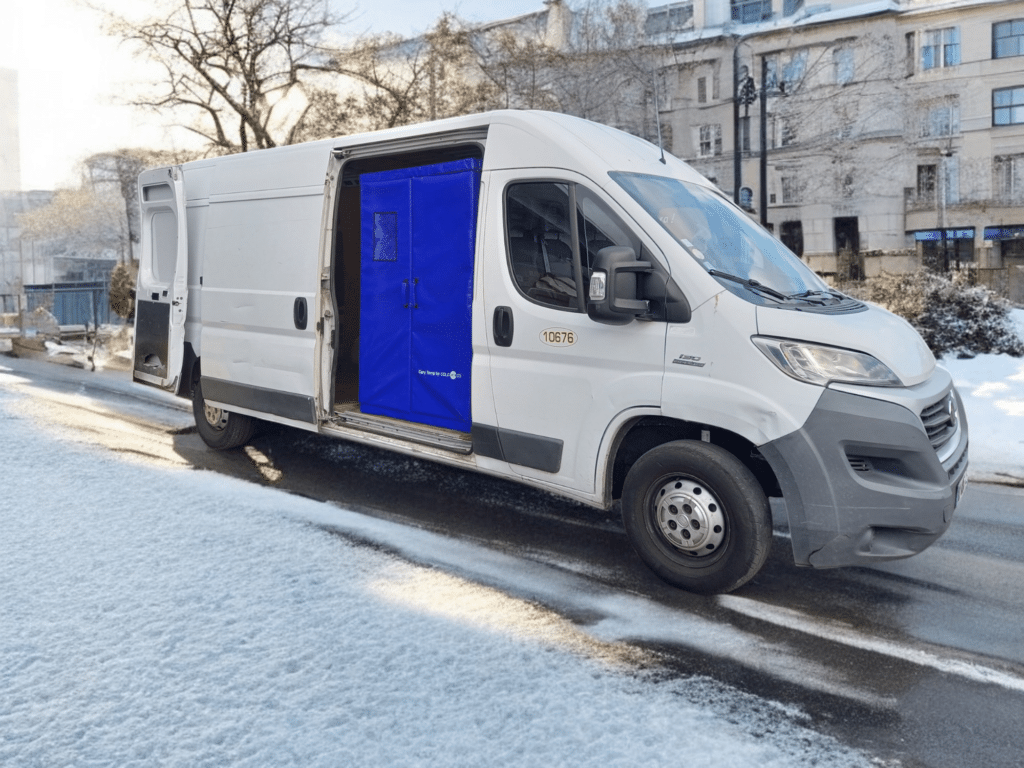

The solution chosen today is based on a dry commercial vehicle of type Fiat Ducato, allowing to combine volume, flexibility and energy sobriety.

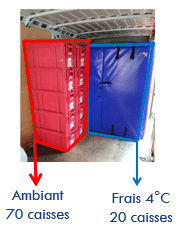

The truck is organized into three distinct zones :

- Up to 70 dry-stored crocodile boxes, directly in the vehicle’s main cell.

- A removable cold room CarryTemp XXLof 2.3 m 3, installed at the rear, can accommodate up to 20 boxes crocos in fees.

- The CarryTemp PM (147 L) or MM (246 L) dedicated to frozen products, placed at the front of the vehicle, at the location of the old passenger seat removed to free up space.

This modular scheme allows products to be distributed by temperature zones, while optimizing the usable volume, on-board weight, and accessibility of products during deliveries. An organization that shows all the interest of passive cold: more flexibility, less technical constraints.

2. Why change model ? Agility, sobriety and reliability at the heart of choice

The transition to a passive cold solution has gradually become established as a concrete response to three major challenges: gaining agility, reducing costs, and making the cold chain more reliable.

2.1. More operational agility

The transition to passive cold in dry vehicles offers a new flexibility in the arrangement of tours :

- Possibility to reorganize the loading on-the-fly: place the frozen items at the front, release the back, adapt the container format CarryTemp depending on the volume of frozen products needed.

- Easy integration of non-standard products: coal bags, large packages, goods not compatible with conventional bins.

- Lighter vehicle, thanks to the use of insulated containers CarryTemp, much lighter than an active refrigeration system.

2.2. A logic of economic sobriety

The switch to passive cooling significantly reduces operating costs :

- Immediate fuel economy : up to 1.5 L of fuel saved every 100 km thanks to the absence of a refrigeration unit to be supplied with energy and the reduction in total on-board weight.

- Reduced vehicle rental costs: a dry van is 20 to 30% cheaper to rent than an equivalent refrigerated truck, while being lighter and more modular

- Less maintenance and technical breakdowns : mechanical cold groups are sensitive to high temperatures and require frequent, often costly maintenance.

Conclusion: All these gains – fuel, rental, maintenance – make the passive investment in cold perfectly controlled, with a depreciation from the first year of operation. A rare performance in a logistics context where the profitability of a fleet is often tight.

With these results, the brand has extended this logic to its logistics partners by choosing to also equip them with CarryTemp solutions. Today, the fleet is composed of 60% internalized vehicles and 40% operated by contracted carriers. By standardizing the equipment, the brand strengthens service consistency, reduces its dependence on heavy refrigeration solutions… and calmly prepares its transition towards decarbonized logistics.

2.3. Tested and approved thermal performance, even in extreme conditions

A field trial was conducted in the middle of the summer to compare the performance of passive refrigeration with those of a mechanical refrigeration unit. Result: the CarryTemp solution, equipped with calibrated eutectic plates, demonstrated better thermal stability throughout the tours.

When the outside temperature exceeds 30°C, the mechanical cold groups are put to the test. The thermal delta to be maintained becomes too high (more than 25°C to keep the products at +4°C), which causes:

• a decrease in efficiency,

• an overheating of the group,

• or even a complete shutdown of the refrigeration system.

Conversely, a eutectic plate continues to diffuse its cold without variation, regardless of external conditions.

This passive robustness makes it possible to cover long tours, up to 200 km, without breaking the cold chain, and without relying on an onboard power source.

Recall that the containers CarryTemp are ATP certified, attesting to their compliance with the requirements for the transport of perishable goods at controlled temperature. An additional guarantee for professionals concerned about health safety and regulatory compliance |

3. A modular logistical organization according to the resources

The success of the passive cold solution depends as much on the performance of the containers as on the daily logistical rigor. For this, each site adapts its organization according to its human and operational constraints.

In some sites, the tours are managed completely autonomously by the drivers. Each driver is responsible for :

- prepare his container CarryTemp,

- load the eutectics plates according to the seasonal protocol (summer/winter),

- and reintegrate the plates into a cold room at the end of his tour.

Other sites have implemented a more centralized organization, with a dedicated logistics agent. The latter:

supervises the preparation of boxes before departures,

controls the placement of cold plates,

ensures the proper docking of vehicles,and ensures the reloading of the plates in a cold room for the following rounds.

This organizational flexibility demonstrates that passive refrigeration can be integrated into very varied environments, without imposing a single structure, but by adapting to the resources and operational maturity of each site.

4. A mixed electric/thermal fleet made possible thanks to the energy autonomy of passive cooling

As part of the gradual transition towards more sustainable mobility, one of the brand’s sites now operates a mixed fleet consisting of 15 thermal vehicles and 5 electric vehicles, out of a total of 20 trucks.

This cohabitation is made possible by the use of isothermal containers CarryTemp, totally energy autonomous. Unlike active refrigeration units, they require no vehicle power supply to maintain the target temperature.

Result: whether it is a thermal or electric utility vehicle, the delivery configuration remains identical, reliable, and without compromise on the cold chain. This thermal independence allows testing electric vehicles without modifying the logistics protocol, while ensuring the same quality of service.

This mixed approach also makes it possible to adapt the engines to the contexts of use:

- Electric in urban environments, for short low-emission tours,

- Thermal in rural or large areas, where autonomy or charging infrastructures are still limited.

CarryTemp plays here a role of technological facilitator, ensuring the continuity of the cold chain, regardless of the energy on board.

5. A tailor-made support, key to success

The success of this change in model depends as much on the quality of the equipment as on the human and technical support.

On this point, COLD & CO played a central role, ensuring close monitoring at each stage of the deployment.

From the upstream phases, our teams worked closely with the client to:

- Guide the selection of containers and plates based on the volumes to be transported, the temperatures to be maintained, and specific operational constraints,

- Define thermal configuration protocols adapted to the different types of tours (duration, distance, season),

- Train drivers and logistics managers in the use of containers, eutectic plate management, and good loading practices,

- Ensure a responsive after-sales service and continuous technical advice, particularly during seasonal adjustments (summer/winter transition, calibration of cold configurations).

This personalized support made it possible to secure the switch to passive cold while raising the skills of the field teams. It is part of COLD & CO desire to be more than a supplier, but a long-term logistics partner.

Do you also rethink your cold chain ?

Are you a food retailer, a logistician or a distributor ?

Contact our COLD & CO experts to study your transition towards a more sober, more flexible and equally efficient logistics.