The thermal challenge +18°C to +25°C at the heart of medical logistics

In the field of the transport of medical devices of in vitro diagnostics (IVD), some entities face a particular challenge: maintaining a strictly controlled temperature between 18°C and 25°C, regardless of the season. In both winter and summer, this requirement for thermal stability is crucial to ensure the reliability of diagnostic results. This level of precision requires rigorous temperature control.

Passive cooling : an economical alternative to refrigerated trucks for transport between +18° and +25°C

To meet this requirement, an electrical or mechanical solution might have seemed obvious.

Using a refrigerated truck calibrated between 18°C and 25°C can become a heavy and expensive solution, especially when only a fraction of the merchandise needs this thermal precision.

Between the initial investment, energy consumption, and lost space, this logistics is often disproportionate to the real need

In this context, the choice of passive refrigeration is essential as a flexible, economical and efficient alternative, particularly suitable for short-term delivery circuits, between 3 and 5 hours maximum, where thermal rigor remains paramount without requiring the infrastructure of a mechanical refrigeration unit.

Isothermal transport 18-25°C : how PCM+18 plates ensure a stable temperature in both summer and winter

This conservation method is based on the use of eutectic plates PCM+18, packaged according to two specific protocols : one for winter and one for summer. This rigor in the preparation allows to precisely control the holding temperature, depending on the outdoor temperature and the transport time. COLD & CO explains to you !

How do PCM+18 eutectic plates work ?

The operation of PCM+18 eutectic plates is based on a simple but extremely efficient physical principle: the change of state at a precise temperature, here +18°C. It is this ability to absorb or release thermal energy during their fusion or solidification that allows maintaining a stable ambient temperature, between 18°C and 25°C.

Their preparation varies according to the season :

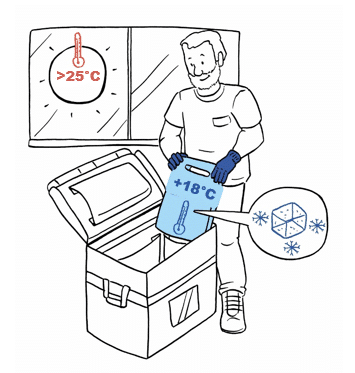

When the outside temperature exceeds 25°C, the plates must be cold-conditioned.

They are first placed in the refrigerator at 4°C until complete solidification (between 24 and 48 hours depending on the total mass).

They are then stabilized at 18°C for about 30 minutes in an oven to avoid a peak cold during their insertion into the insulated container.

Solid at the start, they gradually melt during transport, absorbing excess heat and ensuring an internal temperature below 25°C.

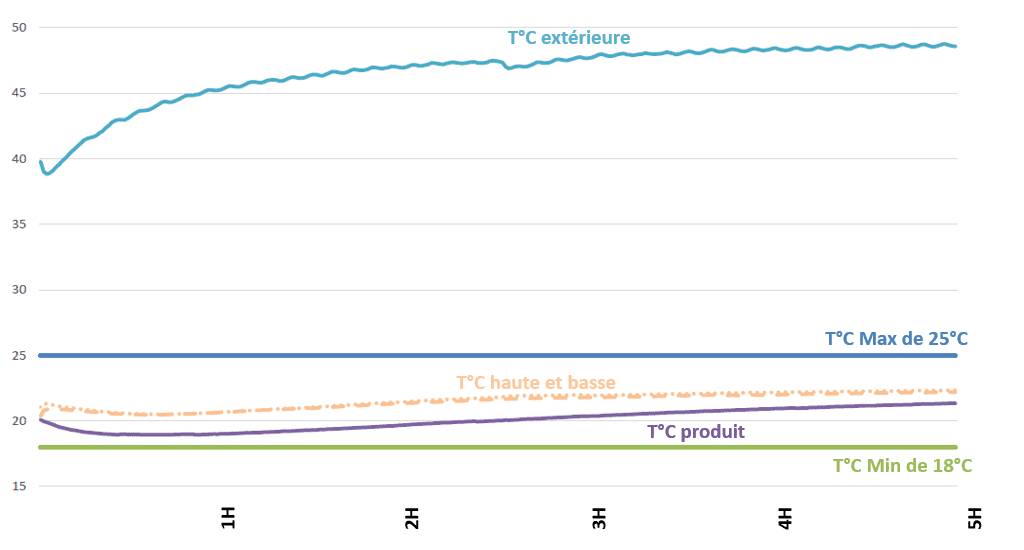

Thermal performance under outdoor temperature greater than 25°C

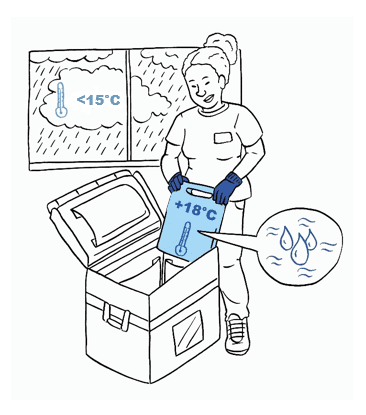

When the outside temperature drops below +18°C, the protocol is reversed. The plates are hot-conditioned, maintained at 30°C for about 8 hours in an oven until complete liquefaction. In this liquid state, they will solidify during transport, capturing excess cold, thus avoiding a drop below the target temperature.

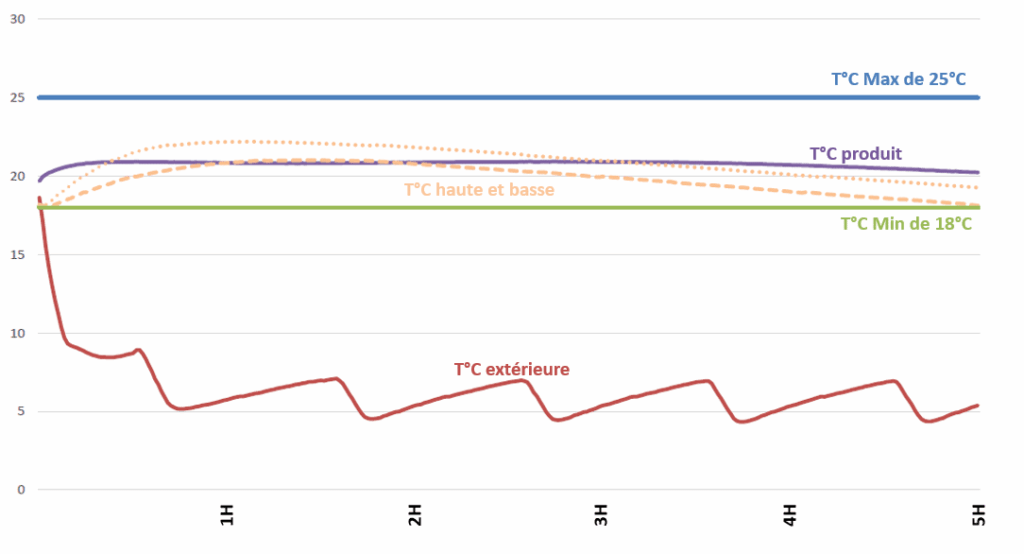

Thermal performance under outdoor temperature below 18°C

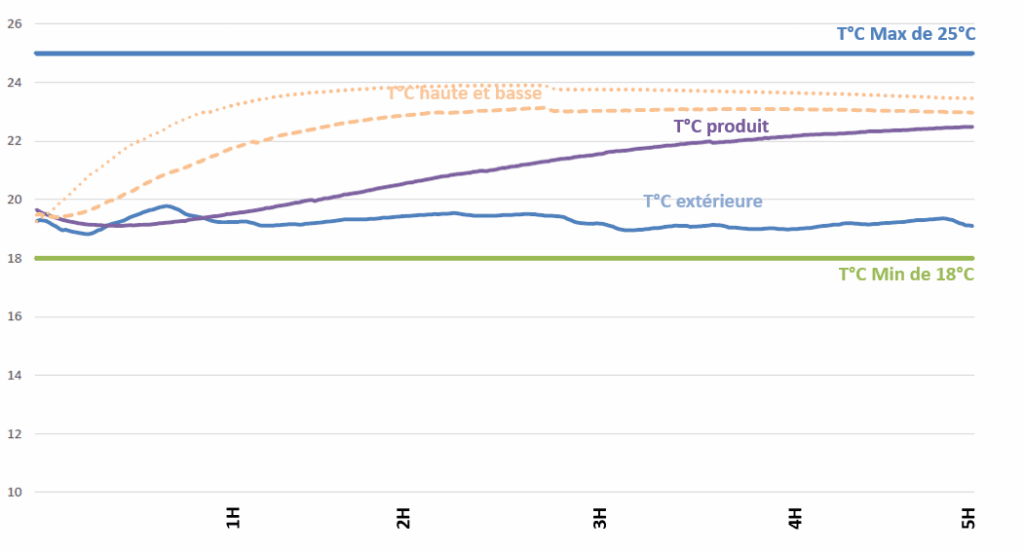

And when the outside temperature is already between +18°C and +25°C? Regardless of the protocol used, PCM+18 plates, whether solid or liquid, will effectively contribute to stabilizing the temperature between +18°C and +25°C. Their ability to react to even minimal deviations ensures a faithful atmosphere in the required range, without overheating or excessive cooling.

Thermal performance under an outdoor temperature between 18°C and 25°C

With a change of state point at +18°C, ambient eutectic plates will melt or solidify depending on the outside temperature, thus absorbing excess heat or cold. This simple and natural mechanism allows to maintain a stable ambient temperature, perfectly adapted to thermosensitive products and medical devices.

The isothermal container CarryTemp XL6 from COLD & CO coupled with eutectic plates +18°C for the transport of medical devices between 18°C and 25°C.

It is in this context that the CarryTemp XL6 solution from COLD & CO has established itself. This self-contained isothermal cabinet, with a useful volume of 600L, offers reliable temperature maintenance without electricity. Equipped with highly insulating polyurethane panels and a thermal diffusion system by natural convection, it keeps products at room temperature thanks to eutectic plates +18°C.

The ergonomics of the CarryTemp XL6 make it easy to integrate into a fleet of standard vehicles. Compatible with the most common vans, it allows you to temporarily transform a utility vehicle into a real insulated vehicle.

An agile and efficient response for the transport of medical devices between 18°C and 25°C :

Thanks to its low weight (30 kg empty), its robustness, its easy maintenance and its ATP certified thermal performance, the CarryTemp XL6 represents a strategic alternative to traditional refrigerated transport solutions. Its use demonstrates that, even on complex requirements such as maintaining between 18°C and 25°C, passive cooling can be both precise, reliable, and respectful of the logistical constraints of the terrain.