1. The context: a growing need for thermal efficiency and performance

Faced with rapidly changing expectations in terms of food delivery, particularly in urban areas and without refrigerated vehicles, a major European retailer turned to COLD & CO with a dual objective:

- guarantee a flawless cold chain,

- reduce logistics and energy costs.

Until now, the retailer had been using isothermal boxes made of expanded polypropylene (EPP), appreciated for their lightness but limited in thermal performance, sturdiness and durability for their use.

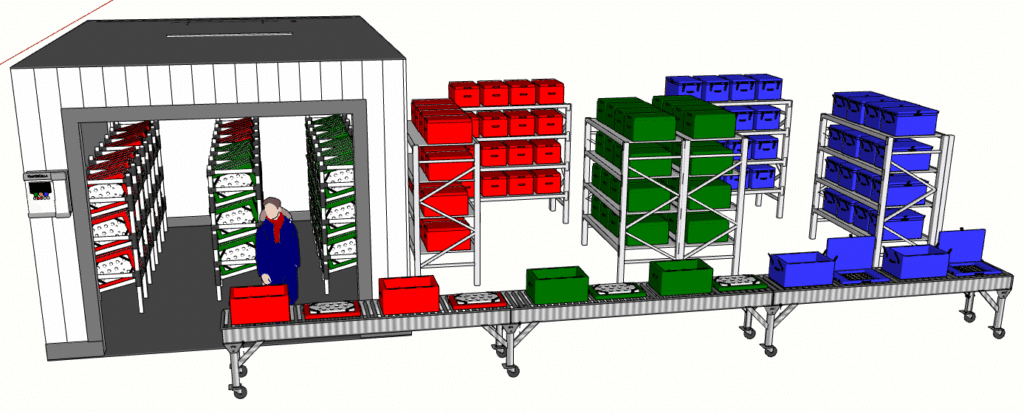

2. From EPP to Freeze/Fresh Conveyor Box: a strategic transition

COLD & CO has developed a high-performance alternative: the Conveyor Box, a reusable, high-insulating isothermal container made of polyurethane panels and a waterproof textile cover. Two versions are available to suit different types of foodstuffs:

Fresh Conveyor Box for fresh produce between 0°C and +4°C, with eutectic plate integrated in the lid

Freeze Conveyor Box for frozen products, with dry ice diffuser tray integrated in the lid.

Tangible gains: performance, savings, sustainability

The switch from the EPP box to the Freeze Conveyor Box has brought measurable and strategic benefits:

1. 33% reduction in cooling requirements

The excellent insulation provided by polyurethane means that the volume of refrigerant required can be reduced by a factor of three – a direct benefit in terms of weight, handling and costs.

2. Less cold, less energy, lower costs

For fresh produce:

With the Fresh Conveyo box and thanks to the excellent thermal insulation provided by polyurethane, the mass of refrigerant required for the Fresh Conveyor Box has been reduced by 33% compared with EPP boxes.

Fewer eutectic plates means :

- less mass to freeze,

- less energy consumed in cold storage,

- and therefore a significant reduction in electrical costs linked to pre-conditioning.

For frozen products:

The Freeze Conveyor Box also reduces the amount of dry ice used by a third, while maintaining the same temperature.

This reduction in consumption means :

- a direct reduction in dry ice costs,

- and a reduction in logistical handling, often time-consuming and costly in terms of protective equipment.

3. Sturdier, more durable equipment

Polyurethane offers superior resistance to EPP: cans last longer, resist impact and withstand frequent washing. Fewer replacements, greater reliability.

4. Ease of use and operational time savings

The integrated cooler in the lid eliminates the need for multiple handling. The whole unit is frozen in a single block, ready for use.

The result: fewer errors, faster, smoother operations.

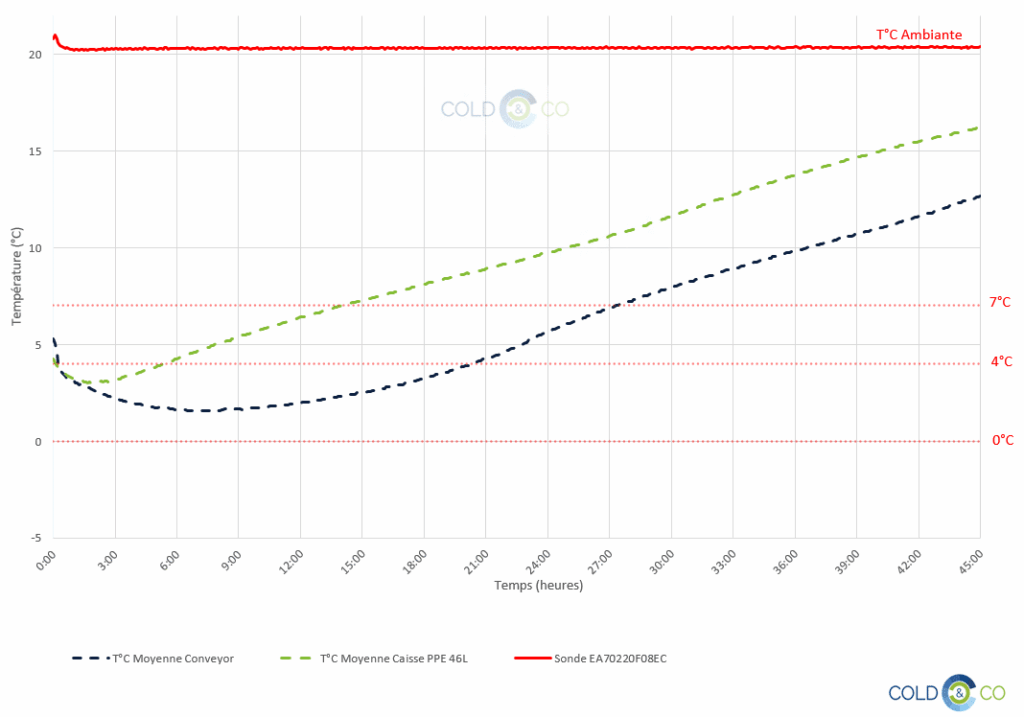

5. Extended temperature resistance: +125% duration

This is a decisive gain. Whereas a simple EPP box keeps products below 7°C for around 12 hours, the Freeze/Fresh Conveyor Box ensures the same performance for 27 hours.

A comparative graph illustrates the difference in thermal performance with the same cold load:

3. Conclusion: a logistical, economic and ecological choice

By replacing its old EPP cases with the Fresh/Freeze Conveyor Box, the retailer has :

- improved cold chain safety,

- reduced logistics and energy costs,

- improved team productivity,

A solution designed for demanding professionals, combining innovation, practicality and durability.

Do you also rethink your cold chain ?

Are you a food retailer, a logistician or a distributor ?

Contact our COLD & CO experts to study your transition towards a more sober, more flexible and equally efficient logistics.